Installation and operating

instructions to customers

Indicative guidelines for designing the installation site/room of a generator set

The following brief instructions intend to assist and advise upon a generator set installation in order to ensure the best possible results for the user-owner.

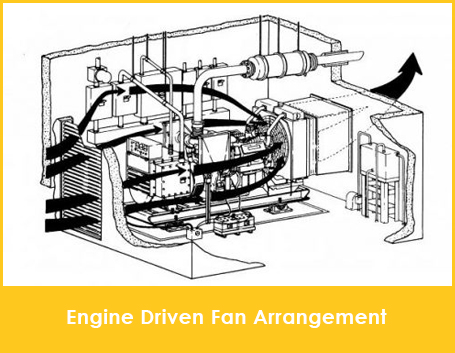

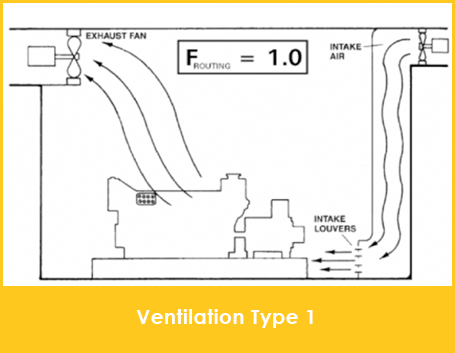

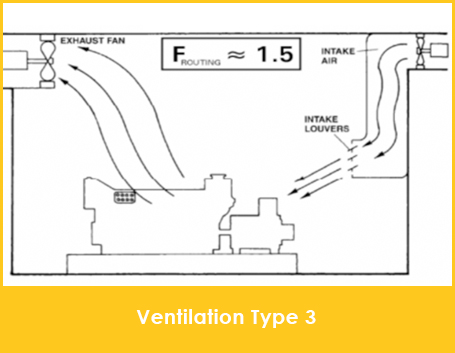

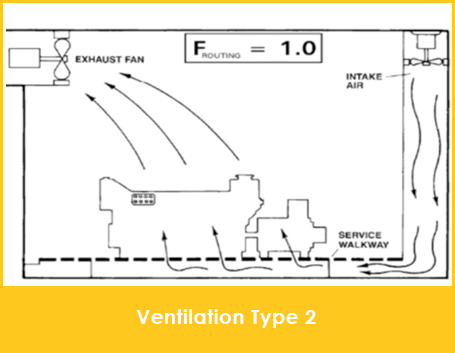

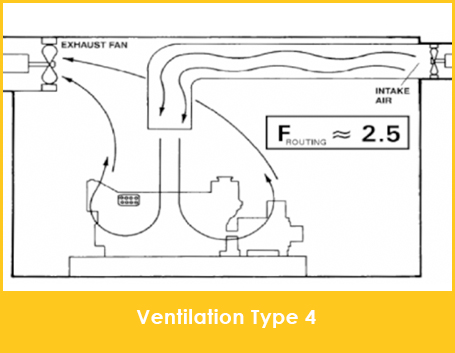

Proper ventilation of the installation site/room

For correct engine combustion and heat dissipation of the motor, plenty amount of air is required. All the specific information for the needed volume of fresh air of each genset model is included in its technical brochure.

Rising temperatures within the installation and operating site of a genset must not exceed 8° – 12°C above the ambient temperature.

Exhaust system

Exhaust piping and silencer should be installed in a way that will allow sufficient space for service access to the maintenance technicians. Proper piping support is crucial to prevent vibration transmission to the generator set.

The entire exhaust system must be properly insulated to avoid heat dissipation/transfer to the installation room.

Finally, for the correct generator set operation, the back pressure of the entire exhaust system should be taken into account and must not exceed the recommended manufacturer limits.

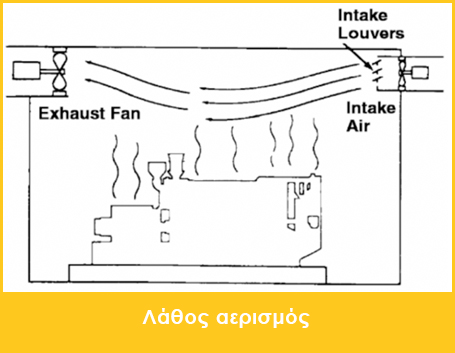

Incorrect Ventilation

Mounting of a generator set

For the proper generator set operation it is crucial to build a completely leveled base/foundation, thus offering adequate seating for the unit. The base/foundation should be of sufficient strength based on the weight of each specific generator set. A proper seating does not affect the critical engine-alternator alignment. A generator set installation on an unleveled surface can cause damages such as distortions of the engine block and torsional stress to the welding and engine foundation iron.

Ιn high-power generating sets (over 1000kVA), Caterpillar provides alternatively special anti-vibration equipment (rubber/spring), which is placed between the generator set and its installation surface (base/foundation) for further vibration isolation. A general rule is to place one pair of anti-vibration rubber/spring near the center of gravity of the generator set and the remaining pieces in equal distances in order to equally distribute the weight of the generator set.

In addition, adequate space around the generator set is necessary for its proper operation as well as for easy access of the service technicians during maintenance intervals (a distance of about 1 meter perimeter is quite satisfactory).

Connecting a generator set

For correct connection of power generators, special attention should be given to the following*:

- Connect the generator set with the automatic transfer panel using a 2×1 shielded cable in order to avoid induced currents.

- Connect a 220V power supply to the generator set’s control and operation panel for battery/ies maintenance (battery charger) as well as for engine preheat system (if included).

Battery system

For the direct/auto-start of the generator set, its battery system should be always under load. For this purpose,

the battery charger must always be connected to the power supply (220V).

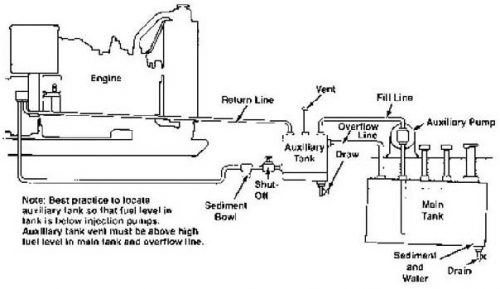

Engine fuel

| The CATERPILLAR generating sets use diesel as an operational fuel. The quality of the diesel fuel used affects the engine performance. Also, the fuel level within the tank is important to be at a lower point than the combustion system (burner, oil pump, etc) to avoid the pressurizing the whole fuel system |

Lately, popular discussions are a fact in what regards to the quality of the available diesel on the domestic market (according to European standard EN 590) and several problems are attributed to it, especially in internal combustion engines. In general, biofuels are promoted by the European Commission, in an effort to limit emissions to the atmosphere:

- Improvement of energy security.

- Separation of energy sources.

- Dealing the Greenhouse phenomenon.

- Strengthening the agricultural sector.

The Disadvantages of using biodiesel are:

- Lower energy content by 10-12% (reduction of the maximum power output).

- Tends to form heavy hydrocarbons aggregates (blocking high pressure systems / fuel filter).

- Extremely corrosive to some elastomers (seals, gaskets, flexible connectors).

- Thinner for deposits (frequent oil change needed).

- Corrosion of metal parts (low resistance to oxidation).

Indicative instructions/checks for uninterrupted operation of generator sets

The following actions should be followed by the operator of a generator set in order for the genset to operate and perform at its full capacity:

- CATERPILLAR constitutes that the operation of generating sets should be with a minimum load of 40%. This will prevent potential liner glazing (as a possible consequence of operating at low loads) and possible high oil consumption.

- The scheduled maintenance of a generator set should occur every 250 hours of operation or annually (whichever comes first) after contacting ELTRAK-CATERPILLAR’s service department.

- Connect the generator set with the automatic transfer panel using a 2×1 shielded cable in order to avoid induced currents.

- Connect a 220V power supply to the generator set’s control and operation panel for battery/ies maintenance (battery charger) as well as for engine preheat system (if included)

- For the proper generator set operation it is crucial to build a completely leveled base/foundation, thus offering adequate seating for the unit. The base/foundation should be of sufficient strength based on the weight of each specific generator set. A proper seating does not affect the critical engine-alternator alignment. A generator set installation on an unleveled surface can cause damages such as distortions of the engine block and torsional stress to the welding and engine foundation iron.

- Visual inspection for leakages.

- Engine oil level check.

- Cooling system antifreeze level check.

- Check the voltage of the batteries and charger.

- Engine temperature check (only if pre-heater is installed).

- The fuel level (within the tank) should be maintained to the maximum level, as much as possible, in order to avoid oxidation.

- The fuel tank should be filled only with diesel fuel that conforms to the Caterpillar’s specifications

- The fuel should be supplied from a reliable supplier in order to avoid any fraud and poor fuel quality..

- Λειτουργία του Η/Ζ τουλάχιστον μία (1) φορά την εβδομάδα, για περίπου μισή ώρα, εφόσον είναι δυνατό.

- Storage of biodiesel at large intervals generates fungi that grow and cause fungal mud which affects negatively the fuel circuit causing operational problems. This is a frequent occurrence on generator sets used as back-up (stand-by) or seasonal solution and the reason is because the biodiesel is stored for long periods. This precipitate is deposited on several parts, for example on the oil pump and the bottom and the sides of the tank, resulting in pump’s malfunction and problematic operation due to tank’s deterioration, which if not cleaned / replaced will affect any remaining diesel left in it, even if this is renewed.).

- Use of a biodiesel oil preservation improver is essential (special antifungals fuel chemical additives and oil stabilizers available from many commercial chemical manufacturers such as wurth, castrol, liqui moly, amsoil, prestone, etc)

- Generator set operation every 48h for about half an hour, to avoid generation of fungal mud

* The purpose of these general installation and operation instructions are only to advice and inform and in no way contain 100% of a complete genset installation instruction set..